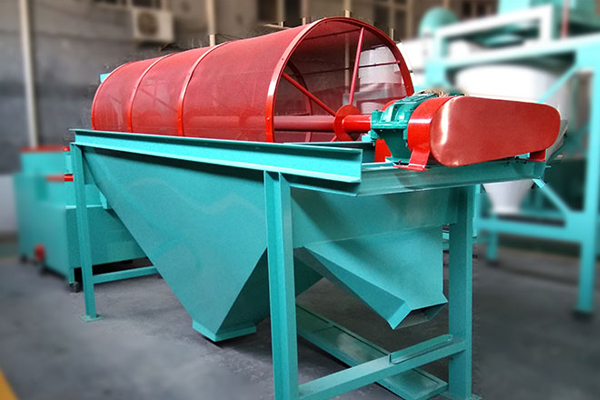

Screening Machine

A screening machine, also known as a screener or a vibrating screen, is a device used to separate and classify materials based on their particle size. It is commonly used in industries such as mining, construction, agriculture, and recycling, among others. The main purpose of a screening machine is to ensure that the material being processed is appropriately sized for further processing or to separate different-sized particles into specific fractions.

Here are some key components and features of a typical screening machine:

Vibrating screen deck: The screening machine consists of one or multiple screen decks, which are typically made of wire mesh or perforated plates. The screen decks are mounted on a frame and vibrate in a controlled manner to facilitate the separation of particles.

Vibrating mechanism: The vibrating screen deck is driven by a motor that generates an oscillating motion. This motion causes the particles to move and separate based on their size. The vibration can be generated by eccentric weights or mechanical exciters.

Feed hopper: The material to be screened is fed into the screening machine through a hopper or chute. The feed rate can be controlled to regulate the amount of material being processed.

Screen openings: The size and shape of the screen openings or apertures on the screen deck determine the size of the particles that can pass through. Different screen decks may have varying opening sizes to allow for the separation of different fractions.

Screening surfaces: The screen deck can be made of various materials, including wire mesh, polyurethane, rubber, or perforated plates. The choice of screening surface depends on the application and the characteristics of the material being screened.

Screening motion and inclination: The screening machine can be designed to have different types of motion, such as linear, circular, or elliptical, depending on the desired screening action. Additionally, the inclination angle of the screen deck can be adjusted to optimize the screening efficiency.

Oversize and undersize discharge outlets: The screened material is separated into oversize and undersize fractions. The larger particles that do not pass through the screen openings are discharged as oversize, while the smaller particles that pass through are discharged as undersize. Separate outlets are provided for each fraction.

Screening machines are versatile and can be customized to meet specific application requirements. They are used to efficiently separate materials of different sizes, remove unwanted contaminants, and ensure product quality and consistency. The size and capacity of the screening machine can vary depending on the application, with small portable units available for mobile operations and large stationary machines for industrial-scale processing.